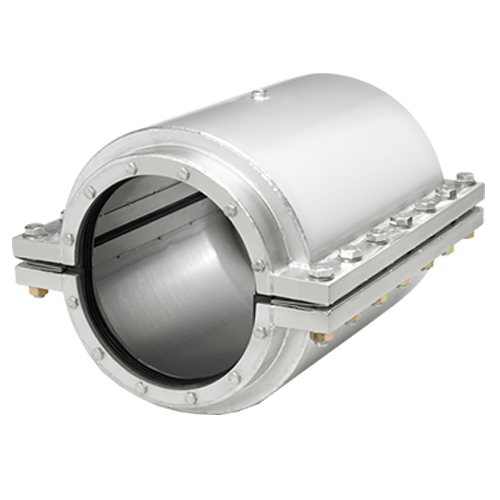

Split Barrel

(Oil & Gas Solutions)

Low Pressure Stainless Steel Split Sleeve

Split barrels are used where leaking couplings and flange connections cannot be taken off the pipe. So, no need to shut down the pipe system. Just place our split barrel over the damaged area. The split barrels are easy to install and corrosion proof. They are available with NBR gaskets and pressures up to 40 bars.

What Are Split Barrels?

With split barrels, it is possible to repair an oil pipe or other kind of pipeline without removing the broken coupling. Moreover, it can be easily installed even under harsh and wet conditions. No special tools are required, only a torque wrench. The clamp is suitable for pressures up to 40 bar and pipes with a diameter up to 1500 mm and length up to 5000 mm.

Design Standards Of Split Barrels

- Body: stainless steel aisi 304/316

- Bolts and nuts: stainless steel aisi 304/316 with PTFE coating – to avoid galling

- Rubber gaskets: NBR axial gaskets are seated in grooves in each half of the split barrrel

- Restraint strips are welded in to prevent the rubber from flowing out during installation

- The initial radial seal is obtained by tightening the end bolts at each end of the barrel

- Depending on the size and weight of the product, a hinge construction will be provided to lift the split barrel over the pipe

- A vent is installed for testing purpose and to enable the medium to escape during installation

- A suitable vent valve is not included